The interest in alternative energies has become stronger in the last years. Among the possible alternative sources, biomass resources seem to be the most implementable in the future.

The use of biomass for producing energy reduces the dependency from fossil fuels, having also low impacts on climatic change and generating new sources of income for agriculture and forestry.

The increasing necessity of wood biomass should be balanced by the creation of storage system cable to assure its maintenance and improving the final characteristics of chips.

Biomass storage has the aim to improve bio-fuel’s quality because it reduces the moisture content in woody materials (at the moment of chipping it is around 60%) and minimize losses of dry matter. In addition, a good storage system determinate also a low level of ash generated by chips after burning increasing the calorific power too. Indeed, chips with high humidity level used in industrial boilers determine low yields in energy production, which are due to the reduced calorific power of the material (we have a loss of 2,44 MJ/Kg of water evaporated) increasing the steam emission too. Steam production entails negative effects on smoke’s depuration; these are due to chemical corrosive phenomena caused by the water condensation.

Drying poplar chips is a process influenced by different factors related to microclimates, chips size and storage methods.

Biomass degradation can slow down using indoor and outdoor storage methods. In the first case, for storing is important the conservation methods, the ground level storage surface, the covering or the pile (it could be uncovered too), the form and the dimension of the pile, the chips’ mixture.

For the outdoor storage, it is important to choose the correct ventilation system (cold or warm air, or without ventilation). The last system allows to limit product losses, but this advantage do not justify the high cost of production.

On the basis of the premises, the choice of the storage method must be weighted considering logistic problems like space availability, appropriate structure, and convenience.

Chips size is another very important parameter that determines the storage quality. A small chip increases the available surface for microorganism which can act in degrading process. In addition, small chip size has combustion problems influencing negatively both efficiency and maintenance costs.

For these reasons Panacea group has conducted different kinds of experiments on chipped poplar Short Rotation Forest chips, with the aim to define an efficient, economic and useful storage system

We performed experiments on 6 piles of poplar chips located on cemented surface. The piles had a conic pyramidal form (height 6meters, width 10 meters). Three of these were covered with geotexile sheet, the others are uncovered. The geotexile sheet has locked the rain, but at the same time allowed the water transpiration due to the moisture content of the chips.

We performed experiments on 6 piles of poplar chips located on cemented surface. The piles had a conic pyramidal form (height 6meters, width 10 meters). Three of these were covered with geotexile sheet, the others are uncovered. The geotexile sheet has locked the rain, but at the same time allowed the water transpiration due to the moisture content of the chips.

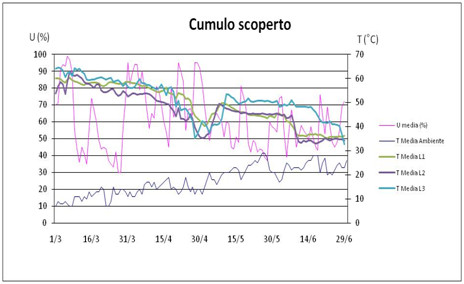

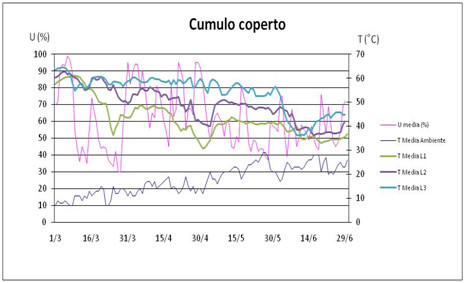

During experimentations, the temperature was monitored by 12 heat resistant probes positioned in specific positions of the pile, which were named: L1, L2, L3 levels, located respectively at 1, 3, 4 meters from the ground.

The probes were connected through a silicone cable to the central computer which communicates data every 10 second. The data are about local microclimate, precipitation, wind speed, external temperature, air humidity and solar irradiation. Moreover, it allowed to monitor the external parameters during all the storage period.

The second part of the study had the purpose to evaluate how the chip size influences the quality of the storage.

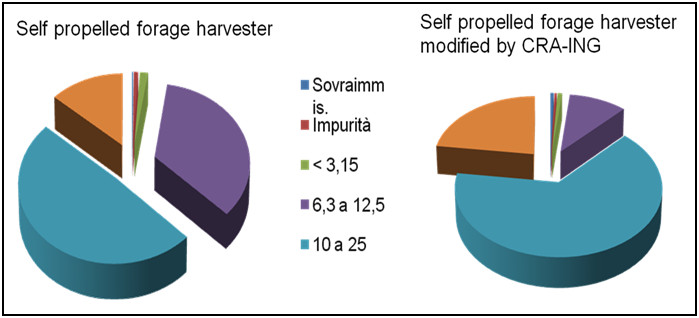

In this experiment three piles were formed by poplar chipped with self propelled forage harvester (Class Jaguar 890) and the other three chipped with self propelled forage harvester modified by Panacea. The modification introduced by Panacea consist of 10 additional fixed blade tilted of 5° respect the rotational axis.

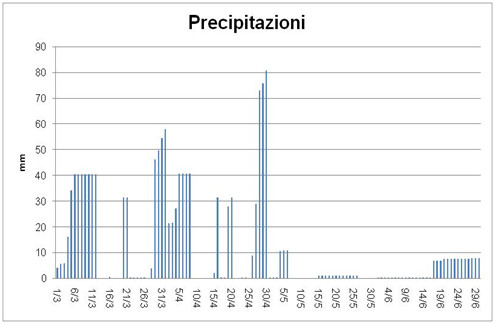

All physical parameters of covered and uncovered piles have shown a very similar trend. It was probably due the thickness of the external layer (30cm around) that act like a protective barrier in uncovered piles. The only difference was found in value “30/4” corresponding to an intense precipitation event. Obviously, the effect of the rain was very relevant on uncovered piles.

|

Uncovered pile |

Covered pile |

|

< < |

|

Trend of physical parameters in uncovered and covered piles |

|

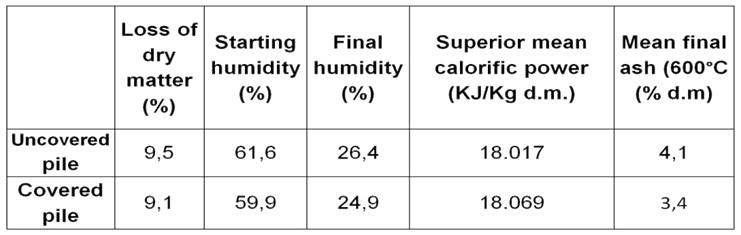

The results have shown that the dry matter (37% average humidity) in covered piles was the 93% of the total mass while in uncovered piles the dry matter (35.5% mean humidity) represented the 59% of the total mass. This indicates that the piles protected by geotexile sheet determined the good quality of chips. However, in both covered and uncovered piles it was registered a high value of calorific power. For the ash evaluation content, the results have shown that mean values are smaller in covered piles than in those uncovered. Probably, it was due to the presence of inert material in uncovered piles.

|

Precipitations |

|

|

Precipitations in storage time |

Trend of phisycal parameters in covered and uncovered piles

In the second part of the study, granulometric chip analysis has shown that the use of self propelled forage harvester modified by Panacea have determined a statistically significant variation in chip size distribution. In fact, Panacea modified machine produced 65% of middle size chips, respect to 48% of standard model, in addition chips of large size became double.

An important aspect is given by the final characteristics of chips quality. In fact, after 4 months of storage, the reduction of dry matter in chips made by self propelled forage harvester modified by Panacea decreased dramatically in L2 and L1 levels. On the other hand, the mean value of the lower calorific power (PCI) and ash content were the same in both cases (16200 Kj/Kg and 3,8 % d.m respectively).

In conclusion, covering piles has determined a more valuable storage of chips than the uncovered system.

However, results can change in relation to environmental conditions. In fact, the same experiment reproduced in other periods has shown non-significant differences between the systems. Indeed, the cost of the geotexile sheet (2euro/m2 ), which can be used for a maximum of 5 years, did not justify the limited advantage furnished.

In the second part, the experimentation demonstrated that is possible to increase the quality of chips storage, increasing chip size, because it is directly related to dryness rapidity. Another important aspect is related to dry matter losses, because it determines losses in energy yield. Losses of dry matter is directly proportional to the storage time, but in storing chips with larger size there is a better inner ventilation and a good water loss, which favored a quicker drying process (mainly in the first months) obtaining a product quickly marketable.

In conclusion we verified that it is possible to improve the chips quality increasing their size.