The dedicated crops for energy production are subject of an increasing interest. The different U.E. directions involve the hierarchical and efficient use of biomass. Among the perennial species that are better suited to the xerothermic conditions find the Cynara cardunculus L. or “Mediterranean cardoon”, multipurpose crop that can be used as raw material for the production of solid biofuels (lignocellulosic fraction and epigean residues threshing) and liquid (oil seed) or in the paper industry for the production of paper pulp of high quality, using primarily the pappus present in the flower heads.

Within the Project “Global Process To Improve Cynara Cardunculus Exploitation for Energy Applications” (Biocard) funded by EU in 2006, Panacea group developed mechanization solutions for Cynara harvesting.  The prototype is an head of a combine harvester able to harvest seeds and leave biomass in windrow that will be subsequently harvested by baling machine in a single operation. In this way the derived particles can be used for different conversions, such as achenes oil for biodiesel production and energy production from the combustion of biomass. From Cynara Cardunculus, in fact, is possible to obtain biomass for energy, seeds for oil and pappus for fine cellulose.

The prototype is an head of a combine harvester able to harvest seeds and leave biomass in windrow that will be subsequently harvested by baling machine in a single operation. In this way the derived particles can be used for different conversions, such as achenes oil for biodiesel production and energy production from the combustion of biomass. From Cynara Cardunculus, in fact, is possible to obtain biomass for energy, seeds for oil and pappus for fine cellulose.

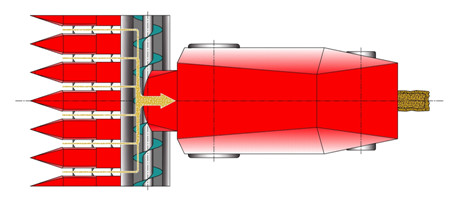

The developed prototype is the result of a fusion between two different head models. It combines the six row maize head, placed in the upper, with the standard wheat head, in the lower part (Fig. 1). The first one serves to detach heads to be sent to the threshing system of the combine harvester, whereas the second one performs the mowing, the conditioning and the aboveground biomass windrowing among the combine harvester wheels. Residues derived from head-threshing are left on the windrow and the seeds are then harvested by the combine harvester.

The main features of the new header prototype compare to the 2007 ones, are:

- Rolls were modified in order to have the conditioning of the stalks and not the chopping for easily harvesting them during the subsequent baling action;

a full-length mowing bar, placed on the vertical side in the front of the rolls, was added to cut stalks at the base of the plant;

a full-length mowing bar, placed on the vertical side in the front of the rolls, was added to cut stalks at the base of the plant;

- once cut and conditioned, the stalks were moved by the means of a screw extending from the head towards an opening in the combine harvester lengthwise axis, in order to make a compacted windrow on which threshed residues were then left. Such a windrow can be harvested by a baling machine, without the use of any swather; thus, earth quantity in the product and ash production during the combustion phase in power plant were reduced;

- a rectilinear reel was installed with the aim of moving the detached heads towards the threshing system, aided by a screw.

The tests were carried out in Spain in September 2008, collecting 40 ha of crop. This machine, operating at a speed of 1.23 m/s (4.41 km/h), performed well, at about 2.10 ha/h. The potential harvest is estimated to be 6.20 t/ha for biomass and 0.856 t/ha for seeds; hourly production is estimated to be 13.05 t/h for biomass and 1.50 t/h for seeds.

Within the project “ENERBIOCHEM” (http://www.novamont.it/BIT3G/default.asp?id=2484) in the summer 2013/14 at Porto Torres (SS), the Panacea group was engaged in the performance of tests of cardoon harvesting.

The operating characteristics detected in Sardinia appeared very different from those found in other regions of Italy, where the possible presence of stones is resolved through stone clearance and/or the grinding stones. In fact, during the cardoon collection in the summer 2013 with the header Panacea, was evidenced the possibility of blade breakage due to the presence of stones and the necessity of the operator to operate with head lifted to prevent the contact blade/stone. The result was that the cutting height was most of the time more than 40 cm thus leaving relevant product not collected in a field.

The operating characteristics detected in Sardinia appeared very different from those found in other regions of Italy, where the possible presence of stones is resolved through stone clearance and/or the grinding stones. In fact, during the cardoon collection in the summer 2013 with the header Panacea, was evidenced the possibility of blade breakage due to the presence of stones and the necessity of the operator to operate with head lifted to prevent the contact blade/stone. The result was that the cutting height was most of the time more than 40 cm thus leaving relevant product not collected in a field.

Panacea, in collaboration with the company Cressoni, has developed a new prototype for the cardoon collection, with two systems that allow an optimal operation in fields characterized by the strong presence of stones.

The cutting blade is placed on a structure, able to perform an oscillation of up to 150 mm in height, which ends with the structures whose task is to overcome any stones and allow the header to follow the field profile.

The movable structure is supported by 6oscillating structures which are hinged on the fixed frame. On each oscillating structures is placed an organ that transmits the oscillation of the movable part to an angular transducer. This transfers the electric signal to the control unit of the combine harvester so that a raising of the movable part corresponds to a raising of the header. In this manner the head can follow the profile of the terrain.

The movable structure is supported by 6oscillating structures which are hinged on the fixed frame. On each oscillating structures is placed an organ that transmits the oscillation of the movable part to an angular transducer. This transfers the electric signal to the control unit of the combine harvester so that a raising of the movable part corresponds to a raising of the header. In this manner the head can follow the profile of the terrain.

The 6 mobile units can move independently, it follows that the blade can flex adapts to irregularities in the field. In order to allow this, the housing of the lower auger (fixed part) is connected with a foil of harmonic steel to the movable part and is articulated with it through a system of sliding between the metal plates.

Under the movable part it is present a protection structure consists of 6 sledges in the wear-resistant steel in order to safeguard the mobile part by the friction with rocks and stones. The lower auger (300 mm diameter) is equipped with retractable fingers (in leaking from the diameter of the spiral in the front and retractable in the back) that has the task of conveying the cardoon stalks cut and comminuted by the counter-rotating rollers towards the center of the header to be discharged to the ground between the wheels of the combine harvester in windrow.

Above it is mounted a header derived from those used for the maize harvesting, which has the function to detach the capitula conveying them inside of the combine harvester and to direct the stem on the bottom breaking it and then conveying it between the wheels of the combine. The upper header is constituted by 9 groups away from 500 mm from each other.

Each group is characterized by the chains that move the capitula to the screw upper, under the chains are placed two cutting blades that can be adjusted hydraulically from the combine harvester in relation to the capitula diameter and to the diameter of the stem apex. Underlying these are the stalk rolls. These, contrarotating and equipped with 4 blades, have the function to pull down the stem until the capitulum is not detached from the blades, causing simultaneously the comminution.