The plant flowers at the end of the growing season when environmental conditions hinder the production of viable seed. Flower infertility is a useful trait of this crop because it allows preferential use of assimilates for biomass production. Owing to its floral sterility, the giant reed is usually propagated by rhizomes, but the lacking of an efficient mechanized harvesting makes their production very expensive.

Commonly, rhizomes are obtained from manual collection of stumps, composed by a knotted mass of rhizomes that must be further sectioned in order to obtain vegetative material of suitable size to planting. Though the saving of the propagation material passes through the reduction of rhizome size, the weight and the length of rhizomes directly affect the survival of propagation material. Rhizomes 5 cm long showed a lower culms density after one year from planting, but the compensation among number and weight of culms resulted in a comparable yield of above-ground biomass among rhizomes 5 or 10 cm long.

Other propagation methods as the use of cuttings or micropropagated plants are under investigation, and encouraging results have been obtained in some cases, emphasizing the interaction between time of transplant and vegetative material employed. On absence of definitive outcome, the use of rhizomes remains the privileged technique.

Before performing the experiment, the procedure commonly used by Italian commercial nurseries for rhizome production was analyzed. The methodology foresaw root extraction, cleaning, washing, and final partitioning into rhizome, all as separate steps. The extraction was carried out with modified plows, where a system of parallel bars arranged on a crankshaft was placed behind the plowshare. The stumps were left for a few days on the soil surface in order to facilitate their drying, after which they were picked up manually and thrown on a trailer equipped with a bottom grate to facilitate a first cleaning from soil. Once at the farmyard, stumps were washed and manually sectioned with a bandsaw or a hydraulic cutter.

The mechanization of the in-situ sectioning and harvest of the rhizomes should help in lowering the costs of agamic propagation, a labor-intensive and scarcely automated phase, with positive effects on the economic balance of the crop. Bearing this in mind, the Panacea group carried out a test using a modified stump grinder aimed at studying the feasibleness of mechanical sectioning of the rhizomes directly in the field. The quality of mechanically produced rhizomes in terms of homogeneity and ability to generate a new viable plant were also evaluated.

A modified commercial stump grinder (Seppi Star-FC, Seppi Ltd., Bolzano, Italy), with a work width of 104 cm, suitable to operate individually row by row, was tested on March 2011. The tiller was designed to section the rhizomes and extract the rhizome sections from the soil, placing them on its surface. The machine (Fig. 1) had a main rotor with a horizontal shaft of 160 mm of diameter where four radial supports were inserted. These ones were 24 cm apart from each other and the outer ones were distant 16 cm from the left and right ends of the shaft. On each support, six hoes (arranged alternated, three for side) were fixed with screws, for a total of 24 hoes.

In order to favor the desired sectioning of rhizome, L-shaped steel hoes (height 24 cm, width 12 cm, depth 10 cm, thickness 1 cm) have been designed and adjusted so as to completely cover the distance between the supports (24 cm).

|

|

Setting |

||

|

|

1 |

2 |

3 |

|

Distance of cut (cm) |

4,4 |

5 |

6,4 |

|

Engine speed (rev min-1) |

1889 |

1850 |

1621 |

|

Speed (km h-1) |

1,55 |

1,75 |

1,95 |

|

Range |

Low |

Low |

Low |

|

Gear |

1st |

2nd |

3rd |

|

Power take-off (rev min-1) |

198 |

194 |

170 |

Before to run the trial, some simulations were performed with several tractors in order to identify the most suitable work parameters such as forward speed, speed of power take-off (PTO) and working depth. Three settings of the rotary tiller were chosen on the basis of different target cut lengths and were compared.

The rationale that drove the choice of sections size was: (i) rhizomes lengths above 5 cm are suitable for successful establishment of a plantation; (ii) on the other side, rhizome dimensions beneath 5 cm could facilitate their handling (packaging, transport) and allow a saving of the propagation material.

Within the field trial, three main plots (one for each setting), 20 m long and 1 m wide, were randomly selected and each one further divided in four sub-plots 5 m long, these last considered as four replication for each setting.

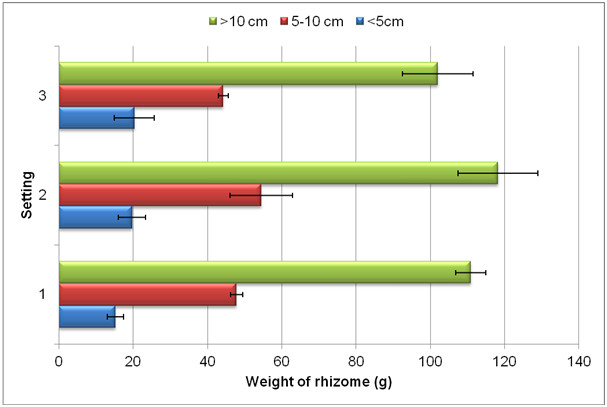

Soon after the passage of the rotary tiller, all sectioned and emerged rhizomes were manually collected. The rhizomes belonging to each plots were immediately closed in sealed, non-breathable bags to prevent dehydration and, then, one by one measured and weighted. The rhizomes were grouped in three class of length: small (<5 cm), medium (5-10 cm) and long (> 10 cm).

In order to evaluate the rhizome viability as function of their size, the rate of germination (survival) and the sprouting ability were evaluated on 144 samples. Two factors were considered, the settings of stump grinder and the length classes, using a randomized block design with four replicates, each consisting of four rhizomes. These ones were placed in pots of 20 cm in diameter with 50% peat and 50% sand and grown in heated glasshouse (20-25°C). After 15 and 30 days from planting the percentage of sprouted rhizomes were registered and the number of emerged shoots counted at the end of the month.

Data were analyzed using the statistical software MSTAT-C (Michigan State University, 1993). Before analysis, percent data were arcsine transformed in order to satisfy the normality assumption.

The action of the stump grinder generated pieces belonging to the central class, but also shorter or longer residues. Being the stump of giant reed strongly irregular, the presence of rhizomes outside the intermediate class (5-10 cm) is due to the action of the machine on very uneven roots not properly hit by the rotating elements. The first results appear, however, encouraging, because the class most represented (5-10 cm) was the one for which the settings 2 and 3 were chosen.

On average, the percentage of rhizomes longer than 5 cm was equal to 88.7% of the total collected rhizomes, with a little variation among the three settings.

The longer rhizome sections produced with settings 1, 2 and 3 had a greater average weight (see figure). This information is of primary importance in relation to the end use of the rhizome. A portion of rhizome suitable for transplanting should weigh between few dozen grams and one kilogram. As previously reported, with all settings it was possible to obtain almost 90% of the rhizomes with a size exceeding 5 cm. Figure 5 shows that rhizomes belonging to the classes 5-10 cm and >10 cm had a suitable weight for use as quality propagation material.

The longer rhizome sections produced with settings 1, 2 and 3 had a greater average weight (see figure). This information is of primary importance in relation to the end use of the rhizome. A portion of rhizome suitable for transplanting should weigh between few dozen grams and one kilogram. As previously reported, with all settings it was possible to obtain almost 90% of the rhizomes with a size exceeding 5 cm. Figure 5 shows that rhizomes belonging to the classes 5-10 cm and >10 cm had a suitable weight for use as quality propagation material.

Beside the reduction of workforce, the mechanization of rhizome sectioning in-situ should allow the obtaining of rhizomes with suitable size in terms of length and weight, assuring at the same time their viability and capacity to produce an adequate number of shoots.

|

|

Class |

Mean |

||

|

Setting |

<5 cm |

5-10 cm |

>10 cm |

|

|

1 |

37,5 |

75,0 |

75,0 |

62,5 |

|

2 |

75,0 |

50,0 |

81,2 |

68,7 |

|

3 |

75,0 |

75,0 |

87,5 |

79,2 |

|

|

|

|

|

|

|

Mean |

62,5 b |

66,7 ab |

81,2 a |

|

For each class of length and every machine settings, a sample of rhizomes were sown in pot in order to analyze if they had retained the germination capacity (survival). As shown in table 3, the longer rhizomes (>10cm) showed the higher rate of survival for settings 2 and 3, respectively 81,2 and 87,5%. Considering the means of settings, regardless the class of length, even if no statistic differences emerged, it can be appreciate as the average survival increased from setting 1 to 3; on the other side, comparing the means of the classes, the rhizomes longer than 10 cm showed the highest value, statistically different from the others (see table).

Giant reed has in its vegetative propagation a limiting factor that can slow down its achievement as energy crop, both from a technical and economic point of view. To this end, albeit the use of rhizome still appears as the better and reliable solution for successful establishment of the cultivation, it presents the disadvantage to be a solution labor-intensive, and hence, costly.

Panacea group has modified the rotating hoes of a stump grinder aimed at to mechanize the rhizomes production of Arundo in nursery. The studied machine was able to section and dig up the rhizomes directly on field and the analyzed settings have allowed to obtain rhizomes in specific classes of length (<5 cm, 5-10 cm and >10 cm) with a good rate of survival and shoot production, therefore suitable for their use in vegetative multiplication of Arundo.

The reduction of rhizome size could aid the handling (packaging, transport), but also the cutback of propagation material with positive aftermath on whole production chain. However, our results have shown that, although viable, rhizomes smaller than 5 cm have no great strength and their production through mechanical sectioning occur at low rate (11-13%). Therefore, the use of the modified stump grinder consents the mechanized sectioning and harvest of Arundo rhizomes of a size currently considered suitable for the successful establishment of a plantation. The worth of system lies in gaining rhizomes ready for packaging, without any further handling.