The riparian vegetation consists of multiform ecosystems adapted on the characteristics of the watercourse where they grow. The management and therefore the safeguarding of river channels is an essential, although costly, activity for a proper preservation of the territory, because the vegetation covering the banks of watercourses affects both the ecological and the hydraulic aspects of the river ecosystem. For this reason, the river banks should be subjected to frequent maintenance, which can also generate substantial quantities of biomass.

The use of the biomass obtained from riparian vegetation for energy goals has been recently suggested, a proposal that meets the need to produce biomass without soil subtraction to food crops and, at the same time, allows the exploitation of riparian biomass, otherwise unused. This could represent an added value improving the economic sustainability of activities ecologically fundamental but unprofitable.

The wide variety of environmental and/or operative conditions characterizing the different typologies of streamside affect their maintenance and justify the search for systems as efficiently as possible and potentially economically self-sustainable. Riparian biomass and residues are mainly left shredded along courses or disposed in landfills as special wastes. The reuse of streamside vegetation can assure an additional revenue covering the costs of buffer management, but, at the same time, the growing requirement for energy production can open new opportunities for the farmer.

Frequently the land reclamation authorities involved in managing the river banks utilize the machines available, suitable for residues removal, but, maybe, inappropriate in case of biomass to destine at energy production. From this viewpoint, the streamlining of the harvesting phase is a key point along the energy chain, especially for a biomass where a rational and efficient handling system is lacking.

In order to develop a strategy allowing addressing the employ of the riparian biomass for energy purposes, the Panacea group, in collaboration with the Consorzio di Bonifica della Maremma Etrusca, conducted a study on chopping systems used for the control of monospecific Arundo donax vegetation in river environment. Two machines (one with hammers and one with knives) devoted to the chopping of the spontaneous plants of giant reed growing alongside the river banks have been compared. The aim of the study were to define the productive potential in terms of biomass obtainable from such contexts, to evaluate the quality standards of the product obtained and to assess the operating capacity of the machines.

Two chopping systems, in use in the land reclamation authority, were compared: a hydraulic forestry mulcher with hammers, mounted on the track excavator, and a hydraulic mulcher with knives, on a self-propelled machine.

The first was a Berti (http://www.bertima.it/en/) hydraulic mulching head (model ECF MD/SB) mounted on a track excavator Hitachi 210-N (fig. 1a). Its operating weight varies from 12 to 16 tons with a rotor mounting 24 double-edged hammers distributed along four axes in a staggered manner (6 for each axis). It can work with any vegetable residue, branches and standing plants up to a diameter of 20 cm and it can be used for marginal areas, the maintenance of watercourses and areas under power lines.

The study was carried out on February 2013 in a land reclamation authority of central Italy "Consorzio di Bonifica della Maremma Etrusca" in the district of Tarquinia (Lazio Region, Central Italy) within the farm "Podere Giulio", Località Piana di Spille (N 42 ° 16.770 - E 011 ° 40.481). A riverbanks section representative of the basin landscape was chosen: it was characterized by a dense monospecific vegetation of Arundo donax L. at dormancy, mowed the previous year (fig. 2). The area was placed inside an agricultural region served by a dense network of carriage roads, allowing easy access to the sites.

Riverbank sections hosting the study. The area was monospecific for Arundo.

A stretch 160 m long, homogeneous for presence of Arundo and for plant density was identified and divided in four areas where the four treatments (hammer single pass, hammer double pass, knives single pass and knives double pass) were assigned. Before the machines start to work, in each area, four 1 m2 sample plots (replicates) were random selected and the plants present were cut in order to measure: the number of plants, the stem diameter 5 cm above the ground, the plant height and the weight of all the plants.

View of the forestry mulcher with hammers (a) and the shredder with knives (b) compared.

The second was a New Speed 150 shredder, an equipment of the self-propelled ILF S1500 8 (http://www.energreen.it/en/). This has a cabin that can rotate 90 degrees, allowing the operator to turn towards the watercourse, while the head, revolving 180 degrees, can work back and forth, halving the passages and thus increasing the productivity. On the head's rotor, 16 Y-shaped cutting elements (formed by three knives) are arranged on four axes (fig. 1b).

Both the machines were proved in a single or double pass. The performances of the yards were evaluated by measuring the working time according to ASABE standard methods (ASABE Standards 2006 and ASAE Standards 2000).

From a morphological point of view, the population of giant reed in this stretch of the riverbank was formed by plants not so much developed in height (less than 4 m), but with a large basal diameter and a good plant density (see table below). The figure that emerges and stands out is the potential yield, reaching 83.3 ton ha-1 of fresh matter (93.3 ton km-1) corresponding to 48,6 ton ha-1 (43.4 ton km-1) of dry yield.

Under normal growing conditions, when included in a farm crop system, being perennial (10-12 years), during its cycle in the areas of southern Europe the Arundo cultivation may reach an average dry matter production of 30 ton ha-1, with peaks of 40 tons ha-1. In some cases, yield values around 100 ton ha-1 of fresh matter has been reported. Hence, as can be appreciated, the data observed represent levels of particular interest. However, the reader must be aware that, since the area controlled by the land authority is quite extensive and the work carried out by the operators recurring at intervals not always regular, such results may vary and to be dependent from various factors as predominance of Arundo, age of the plants, harvesting time.

|

Parameter |

|

|

|

Plant density |

p m-2 |

37,4±2,1 |

|

Plant height |

cm |

355,6±8 |

|

Stalk basal diameter |

mm |

14,2±0,5 |

|

Plant weight |

kg m-2 |

8,31±0,8 |

|

|

|

|

|

Studied area |

ha |

0,16 |

|

km |

1,14 |

|

| YieldFW |

ton km-1 |

93,3 |

|

|

ton ha-1 |

83,3 |

|

YieldDW |

ton km-1 |

48,6 |

|

|

ton ha-1 |

43,4 |

The action of the shredder knives improved enormously, and in a manner statistically significant, the density of the chopped Arundo (see table below). On average, the two products differed of almost 30 kg m-3 (77.9 vs 107.2 kg m-3), a difference that must be evaluate in view of the logistic organization, since increasing the bulk density, the number of trips required to confer the biomass will reduce with clear economic advantages.

The divergence was particularly evident when the plants were chopped in two passes. For both the implements, the double pass increased the values of bulk density, reaching a significant statistical difference with two passages of the shredder (equipped with knives). It should be outlined that the double passage with the shredder allowed an increment of bulk density near 50% respect to the one pass of the same machine or two passes with the forestry mulcher (with hammer), but also a rise of almost the 80% if compared with the product obtained with one pass of the latter. As for the moisture, even in this case it should be stressed that, regardless the machine, the best result was obtained by performing two passes.

|

Passes |

Implement |

Mean of passes |

||

|

|

Hammers (kg/m3) |

Knives (kg/m3) |

(kg/m3) |

|

|

1 |

71,4±2,8 b |

85,9±1,9 b |

78,7±3,0 B |

|

|

2 |

84,4±4,7 b |

128,4±4,9 a |

106,4±8,16 A |

|

|

Mean of implement |

77,9±3,6 B |

107,2±7,6 A |

|

|

The type and the degree of biomass comminution may affect the fuel performances in the dedicated boilers, that accept homogeneous fuel particles within specified size limits. The most critical fractions are the extremes: oversize particles tend to arching or bridging, clogging the conveyor system of the heating plant; the finest fraction (<3mm) supports the bacteria proliferation, reduces the fuel preservability and increases the production of ash.

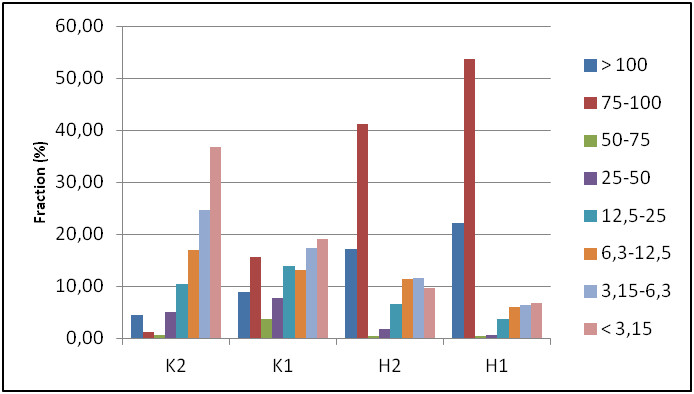

The obtained results showed clear indications about the influence of the treatment on particle size distribution (see figure below). On the whole, the four kind of feedstock produced by the treatments were rather heterogeneous in terms of particle size distribution. The proportion of the largest fractions (>100mm and 75-100 mm) progressively increased according to the following order of the treatments K2<K1<H2<H1, arriving to represent more than 75% for the single pass with the forestry mulcher (H1). Simultaneously, the percentage of undersize particles (<3,15 mm) revealed an opposite tendency (H1<H2<K1<K2), reaching a peak (36.7%) when the Arundo was comminuted using the shredder bringing the knife elements.

For easier understanding, the different fractions have been merged into less functional classes (table 5) in order to stress also the differences for the fraction of the accepts (50 to 3.15 mm), particles within commercial size specifications. The use of the shredder (K2 and K1) resulted in the highest percentages of particles falling within the intermediate interval, and the difference with the product obtained from the forestry mulcher (one or two passages, indifferently) had a statistical significance.

The different action of chopping elements (hammers or knives) coupled with the number of passages of the machines appeared even more evident. The knives cut and chopped definitely the plant tissues, producing a distribution concentrated on the medium sizes (K1), but leaving a remarkable percentage of oversize; with a second passage (K2), the cutting elements furtherly acted on the longer fractions, increasing the percentages of the finer classes. This can be appreciated observing the behavior of the largest and the smallest fractions for K2: the first were reduced by about one-fifth, passing from 24.61 to 5.74%; the second almost doubled, increasing from 19.03 to 36.68%. The action of the hammers was coarser than that of the knives and, rather than a fine comminuting, they brought about a fracture of the plant tissues. Performing just one passage, the product attained was mainly represented by oversize particles. The effect of the second passage caused a significant reduction of the oversize, but, in this case, increasing the fraction of the accepts (almost doubled in H2) and affecting only marginally the rise of the undersize.

Machine performance: mulching head with hammer

The evaluation of the machines performance was limited to the forestry mulcher mounting 24 double-edge hammers since the conditions of soil moisture did not allow to the self-propelled shredder, devoid of tracks, to operate efficiently.

Consistent with the technical terminology required, there were no rest periods or dead times. The accessory time was represented only by the time for turning and maneuver because no adjustments on the machine were made in the field. It should be emphasized that during the work, owing to the high plant density, the operator has been forced in some cases to slow down.

Before the beginning of the test, it was asked the operator to work with the methods routinely used during maintenance of the watercourses. The machine has operated in the transversal sense, starting from the top and climbing down towards the bottom of the riverbank, near the watercourse. When finished, it moved longitudinally in the neighboring area. The cutting approach followed by the operator foresaw an initial intervention to lower the height of the plants and a second phase when all the biomass was chopped. In the case of treatment H1, the prove was finished, while for the double passage (H2), the operator passed again on the shredded biomass.

The effective time registered was 86%, working with an operating speed of 0.55 m s-1 (1.98 km h-1). The effective field reached the value of 0.07 ha h-1 corresponding to a material capacity of 6.70 t h-1 of chopped biomass.

|

Standard time |

||

|

Effective time |

% |

86,45 |

|

Accessory time |

% |

13,55 |

|

Turning |

% |

13,55 |

|

Adjustment |

% |

0,00 |

|

Operating time |

% |

100,00 |

|

|

|

|

|

Machine performance |

||

|

Field efficiency |

% |

86,45 |

|

Effective speed |

m s-1 |

0,64 |

|

Operating speed |

m s-1 |

0,55 |

|

Theoretical field capacity |

ha h-1 |

0,09 |

|

Effective field capacity |

ha h-1 |

0,07 |

|

Material capacity |

t h-1 |

6,70 |

The careful management of river channels, in addition to large amounts of woody biomass, could provide feedstock for bioenergies, thus representing an added value improving the economic sustainability of activities ecologically fundamental but unprofitable. The use of riparian vegetation for energy is an area of enormous potential that is attracting particular interest especially since it avoids the deprivation of surfaces to food crops and at the same time permits to fulfill ecologic function recovering debris otherwise unused.

Frequently the land reclamation authorities involved in managing the river banks, like the one hosting the study, utilize machines suitable for residues removal, but, maybe, inappropriate in case of biomass to confer at energy production. With the present study it has been possible to evaluate both the interestingly yield potential obtainable from the management of monospecific riparian vegetation of Arundo donax and the adequacy of the available machines for feedstock production. The comparison among a hydraulic forestry mulcher mounting 24 double-edge hammers and a shredder mounting knives has shown the better characteristics of the product obtained from the latter in terms of density and particle size distribution, performing both one or two passages. The comminution operated by the tested machines yielded a feedstock unsuitable for firing residential boilers, due to the relatively the frequent presence of oversize and/or undersize particles but acceptable for industrial plants. Clearly, the technical indications should then be evaluated in terms of convenience in an accurate economic assessment of the chain. Studies such this may be helpful and are needed to understand if the mechanization lines available in a land authority can be adapted for reconverting the production towards energy uses or the obtaining of a suitable fuel requires the employment of specific implements.

Since the rational exploitation of riparian vegetation presents further chances of improvement, an effort will be required for the identification of the most suitable mechanization lines encompassing the harvesting of chopped biomass and the logistic. At least two approaches may be proposed. A first line of mechanization can foreseen the simultaneous cutting and harvesting of the biomass that, through an aspiration system, is automatically conveyed to a dumper integrated with the machine or on a towed trailer. A second solution could be developed through the use of innovative mulchers equipped with a conveyor belt assuring the removal of the chopped vegetation from the inclined (or horizontal) plane of the embankment and its harvesting by means of a self loading wagon.

In view of the added value that the use of riparian vegetation could have in the coming years (re-use of residuals coming from an activity required for the protection of the territory, without subtracting surfaces to food crops), the definition of strategies for the sustainable recovery recovery of this biomass (especially common reed ) will constitute an exciting area of study.